- Overview

- Torque Chart

- Brochures & Comparisons

- Technical Documents

- Videos

- White Papers & Case Studies

Easytork Vane Actuator (EVA Series) Product Line

Our patented vane actuator design is a proven industry leader in valve actuators.

Key features of the Easytork quarter turn 90-degree pneumatic rotary vane type style valve actuators

+ Patented spring-less design directly replaces spring return actuators for fail safe

+ Eight models with torque of up to 46,000 in-lb at 80 psi

+ Each model can be used for open close or modulating: double-acting, fail-safe, fail position (open or close)

+ Temperature range of -40 degrees F to 248 degrees F (-40 degrees C to 120 degrees C)

+ American Water Works Association (AWWA) C541 Compliant

+ 2 year / 2 million cycle warranty

For any questions about our vane actuator, please contact us!

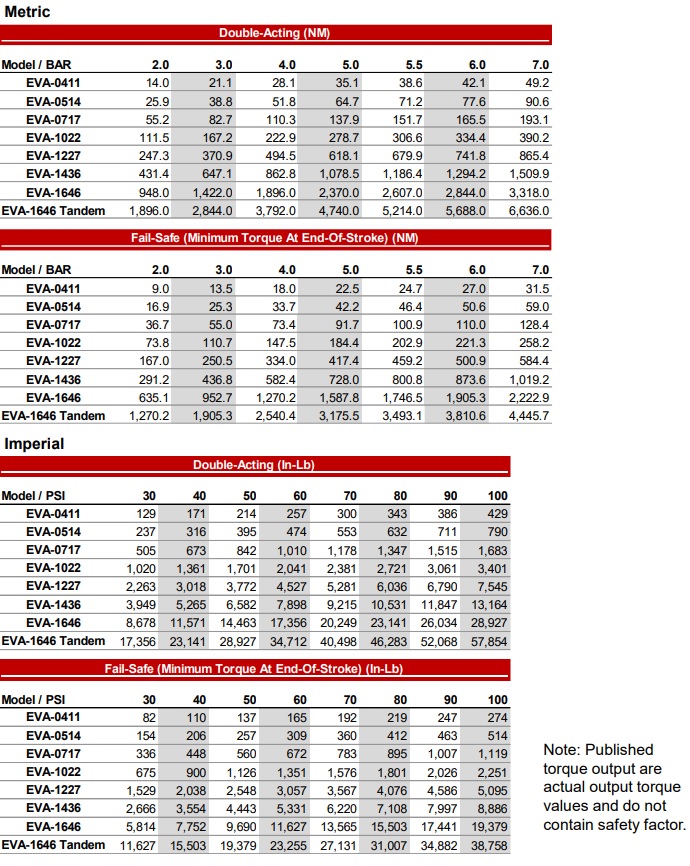

| EVA Model | Double Acting Torque @ 80 psi (in-lb) |

Fail Safe Torque @ 80 psi (in-lb) |

Flange Patterns (ISO 5211 and Non-ISO) |

Standard Drive Insert | VDI / VDE 3845 | NAMUR |

|---|---|---|---|---|---|---|

| EVA-0309 | 195 | 127 | F03, F04, F05 | 9mm (0.35") Square | √ | √ |

| EVA-0411 | 343 | 219 | F03, F04, F05, F07 | 11mm (0.43") Square | √ | √ |

| EVA-0514 | 632 | 412 | F04, F05, F07, 3.25" | 14mm (0.55") Square | √ | √ |

| EVA-0717 | 1,347 | 895 | F05, F07, F10, 3.25" | 17mm (0.67") Square | √ | √ |

| EVA-1022 | 2,721 | 1,801 | F07, F10, F12, 3.25", 5.00" | 22mm (0.87") Square | √ | √ |

| EVA-1227 | 6,036 | 4,076 | F10, F12, F16, 3.25", 5.00" | 27mm (1.06") Square | √ | √ |

| EVA-1436 | 10,531 | 7,108 | F12, F16, 5.00" | 36mm (1.42") Square | √ | √ |

| EVA-1646 | 23,141 | 15,503 | F16, F25 | 46mm (1.81") Square | √ | √ |

| EVA-1646 Tandem | 46,283 | 31,007 | F16, F25 | 46mm (1.81") Square | √ | √ |

Full Catalogs

Easytork Vane Actuator (EVA Series) and Accessories - Catalog (PDF)Brochures

Easytork One Page TeaserSize Comparison

Comparison of Various Actuators

Comprehensive EVA Overview

Case Studies

Fugitive Emissions - Easytork's Patented Design Allows for Significant Reductions of Actuator Emissions from Pneumatic SystemsMining Industry - Easytork Performance in Dirty Air Environment

Skid Manufacturing - Easytork's Significant Advantages

Water Industry - Using Water to Drive the Easytork Actuator

Press Coverage

Valve World MagazineCut Sheets

EVA-0309EVA-0411

EVA-0514

EVA-0717

EVA-1022

EVA-1227

EVA-1436

EVA-1646

Tandem EVA-1646

Technical Data

EVA Technical Data and Build of MaterialInstallation and Operation Manual

EVA IOMCAD / 3D Drawings

Please contact us directly for CAD / 3D drawings.White Papers

Valve World MagazineCase Studies

Fugitive Emissions - Easytork's Patented Design Allows for Significant Reductions of Actuator Emissions from Pneumatic SystemsMining Industry - Easytork's Outperformance in Dirty Air Environment

Skid Manufacturing - Easytork's Significant Advantages

Water Industry - Using Water to Drive the Easytork Actuator

An End User's Three-Year (and On-Going) Journey with Easytork:

“I am a believer in these actuators… I am certain there are others out there who have been looking for the same solution."

Topic 1: Size and weightTopic 2: Dirty or wet environment

Topic 3: Ease of use

Topic 4: Accuracy for control valve

Topic 5: Where the end-user is today with actuation

Need More Information? Let Us Help You.

314-266-6880, info@easytork.com, or Live Chat with Customer ServiceSend Us a Message (Same Business Day Response):