Re-designing Vane Type Actuators for Improved Rotary Control Valve Performance

The article addresses and details how improving actuation for rotary control valves can significantly improve the HDRL of control valves.

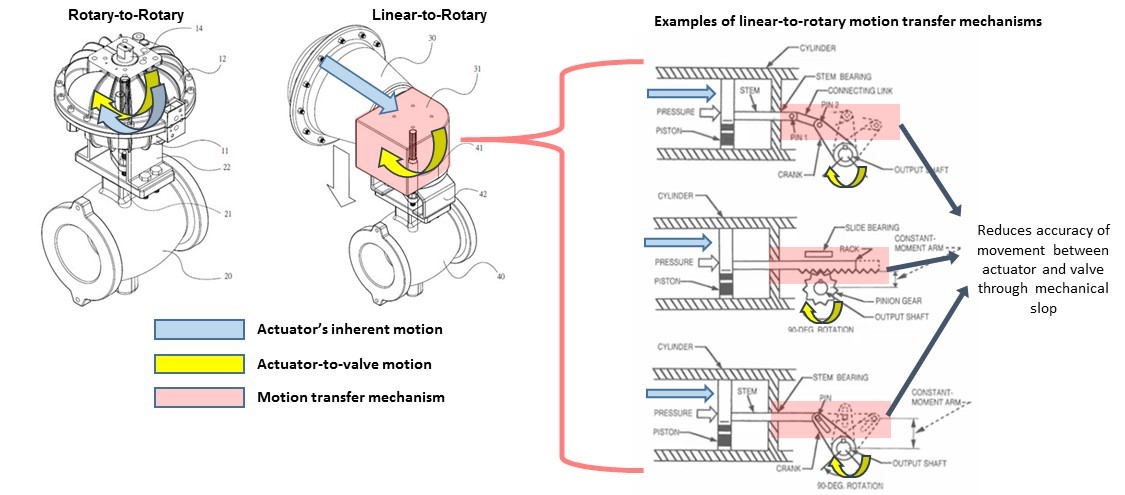

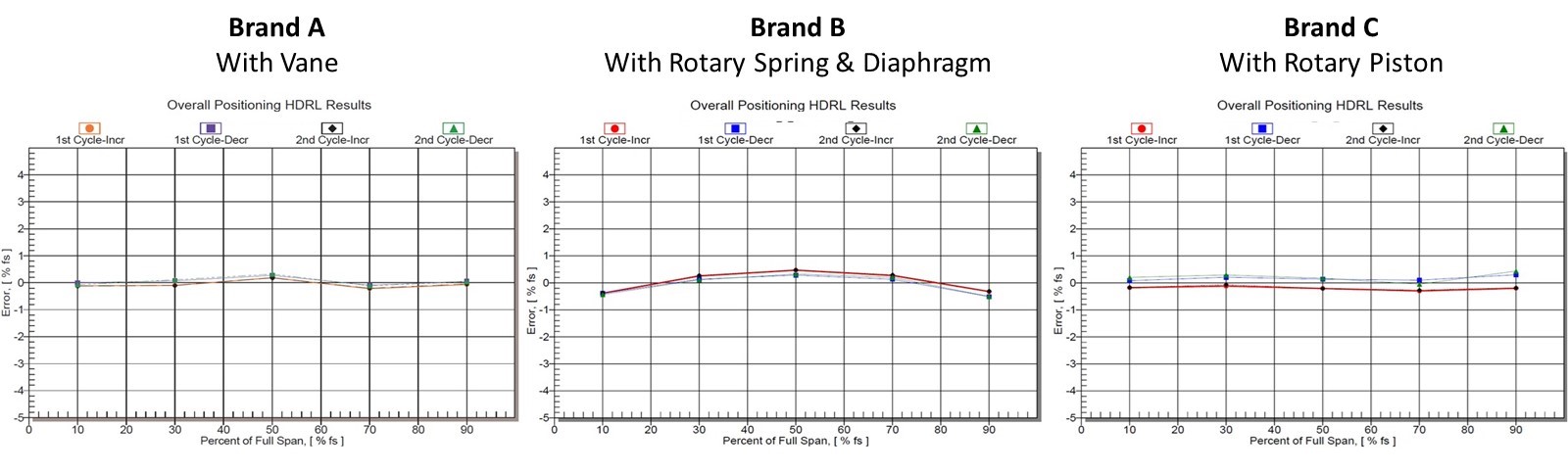

Addressing control valve HDRL performance (“hysteresis, deadband, repeatability, and linearity”) has a substantial effect on process plant efficiency and overall profitability. Understanding this, the industry began its earnest march towards improving control valve performance starting in the 1990s through a combination of diagnostic tools to identify poor control valves, and by improving the actual control valve hardware comprised of positioner, actuator, and valve. While there have been significant improvements made in diagnostic equipment and positioners for the control valve market, actuators and valves are still fundamentally unchanged, until now. The rotary actuator market can be divided into rotary-to-rotary and linear-to-rotary. Vane actuators are the only rotary-to-rotary designs in the market. This design generates inherent rotary motion that can be directly used by a rotary valve. Rotary spring & diaphragm and rotary piston style actuators are the common technology for rotary control valves. However, they are the linear-to-rotary design that generates inherent linear motion to be used by a rotary valve through a motion transfer mechanism. As seen in FIGURE 1, motion transfer mechanism causes mechanical slop and the degradation of control valve performance.

Figure 1

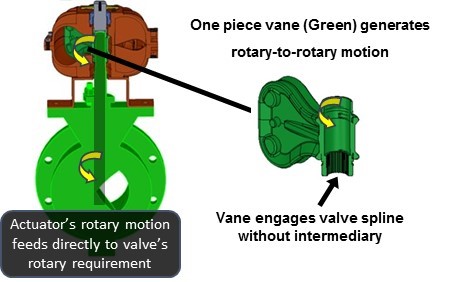

As much as a linear-to-linear actuator makes sense for a linear globe valve, a rotary-to-rotary actuator capable of direct mounting to a valve makes sense for a rotary segmented control valve FIGURE 2. Until recently, direct mount-ability of vane actuators has not existed in the market as vane actuators have traditionally required a mounting hardware (bracket and coupling) to conjoin the actuator with the control valve. Mounting hardware, like the motion transfer mechanism, contribute to mechanical slop and negatively affect deadband.

Figure 2

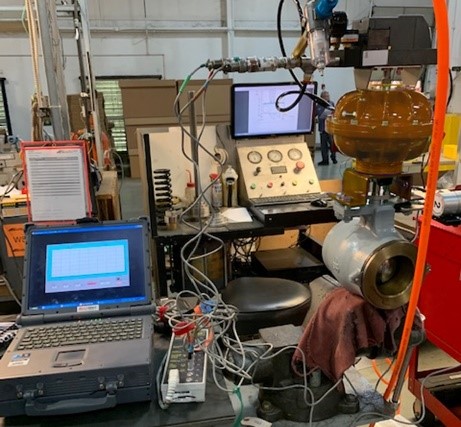

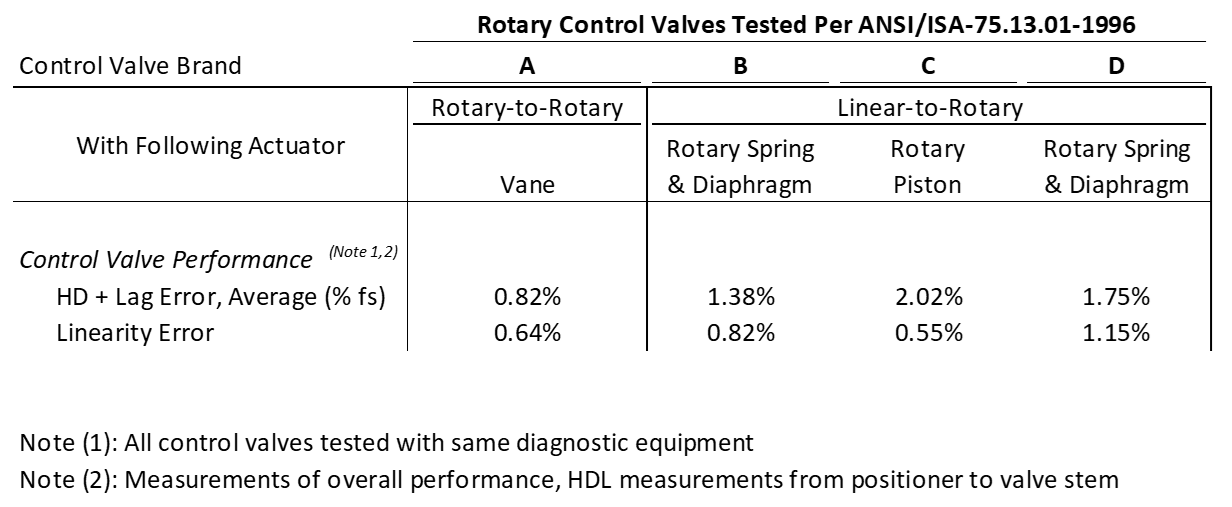

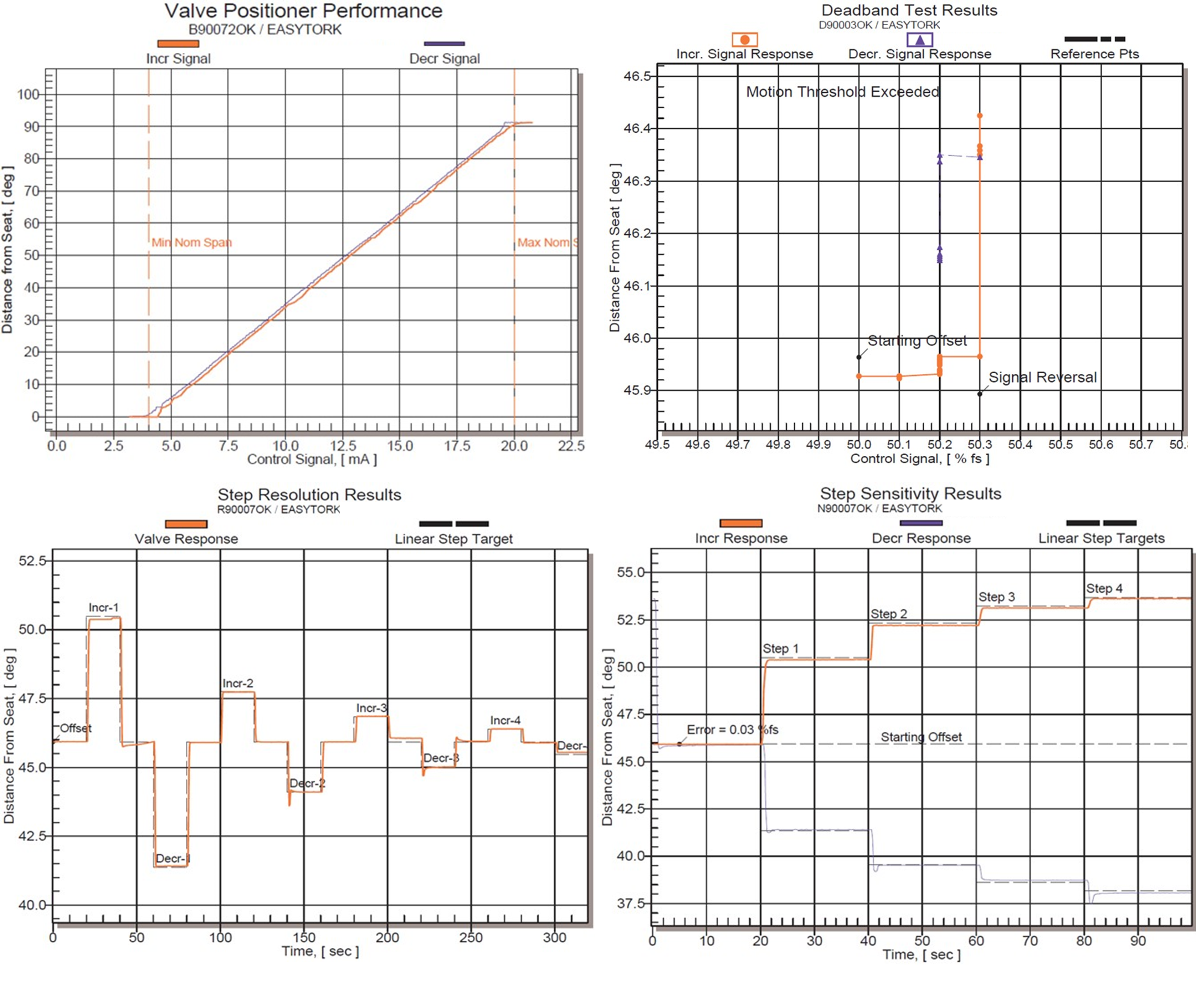

The fundamental question for the reader is if the overall control valve HDRL performance improvement with vane actuators capable of direct mount are statistically significant over linear-to-rotary actuator designs, and the answer is yes. Refer to FIGURE 3 for control valve performance comparison chart and FIGURE 4 for Deadband Test Results, Step Resolution Results, and Step Sensitivity Results of control valves with direct mount vane actuators. As seen from these test results, these vane actuators consistently outperform linear-to-rotary actuators.

Figure 3

Figure 4