Mining Case Study: Harsh, Corrosive, Dirty Environment

How Easytork Actuators Thrived in One of the Most Challenging Applications in Actuation While Reducing Total Cost of Ownership for a Mining Operator

A gold mine with compressors located on the surface, with air lines that run 3,000-4000 ft *914-1,219m) underground to feed actuators with little filtration

Industry experts in mining know clean instrument air is a premium in mining application areas due to the cost of building and maintaining the air system in remote areas. Instrument air aside, the quality of the environment air in mines is very poor. With most actuators in hard-to-access locations, it is doubly imperative that any system be able to withstand both poor instrument and poor environment air to reduce maintenance cost and system failures.

Easytork actuator complements the mining industry requirements with an actuator that:

1) Performs well in extremely poor instrument and environmental air

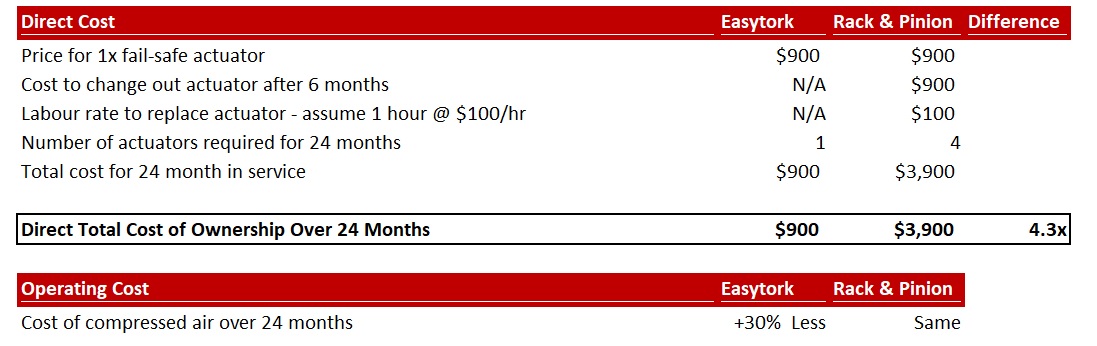

2) Reduces direct cost of ownership over 24 months of over 77%

3) Reduces operating cost by using ~30% less air

CHALLENGE:

A gold mine in Canada had challenge maintaining a clean instrument air system. The end-user’s compressor is located on the surface, with air lines that run 3,000 to 4,000 feet underground to feed actuators with little filtration. The resulting air lines have extremely poor air quality with extreme moisture and rust. These factors all contribute to high maintenance costs (actuators and filters) and increased actuator turnover. The initial challenge was to find an actuator with good performance with dirty air to reduce cost of maintenance. The secondary challenge is to reduce operating costs on air systems.

SOLUTION:

Starting in 2015, and continuously since, Easytork actuators were installed at the gold mine for paste fill, mine dewatering, process water feed, among other applications. As of 2017, Easytork actuators have been problem-free. Easytork is considered a low maintenance actuator, which does not require emergency replacement or cleaning of actuator or filter. Easytork also reduces total-cost-of-ownership by consuming ~30% less air.

RESULTS:

Need More Information? Let Us Help You.

314-266-6880, info@easytork.com, or Live Chat with Customer ServiceSend Us a Message (Same Business Day Response):