ECA-F Series Independent Test Results

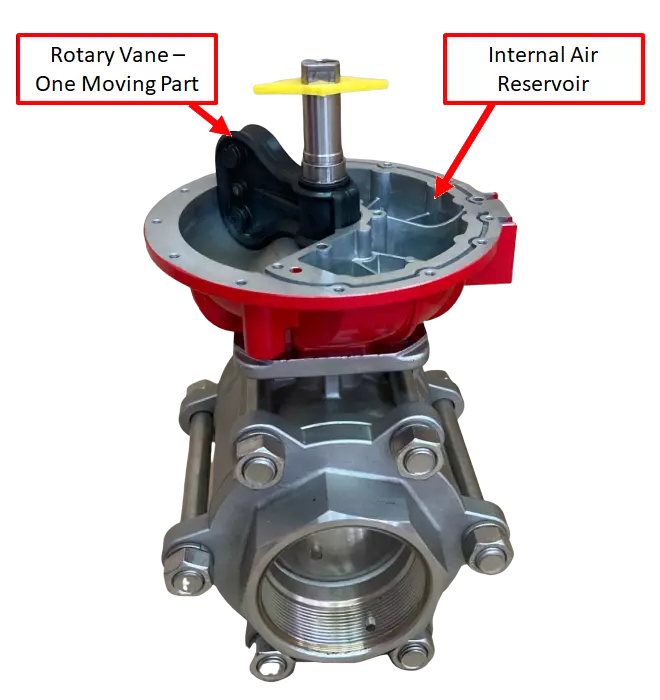

Easytork’s pneumatic actuator working principle has made many major industry advancements. We have improved on external air reservoirs used in emergency shutdown valves by incorporating the air reservoir directly into the actuator. Similar to springs' action in a spring return actuator, when there is air failure, the pressurized air stored in the air reservoir drives the Easytork actuator to fail safe.

Note: You may turn on volume directly in video

By eliminating springs and having only one moving part, Easytork exponentially increases reliability and efficiencies of pneumatic systems - these main features to follow.

How do you monitor the condition of springs? You can't without expensive positioners and a lot of training. You can, however, easily monitor and take preventative actions when actuators leak. Predictive maintenance is made easier through Easytork's air reservoir fail safe mechanism. And with only one moving part vs. at least five in a spring return actuator, you have less parts that can go wrong.

How much time is your maintenance spending to replace an actuator's O-rings? Seal failure is the most common failure point and the probability of seal failure increases through regular usage, poor instrument air, and poor environment air.

It is crazy to us that almost all actuators still use O-rings, when in fact O-rings are meant to be used between two flat non-moving surfaces (static sealing).

Easytork's sealing is not only thicker, but our lip-seal design is manufactured specifically for dynamic sealing which reduces the need for maintenance even in tough environments, constant usage, and dirty instrument air.

Our pneumatic actuator working principle broken down further

Eliminating springs removes another common failure point. Air reservoir avoids spring issues developed over time including: spring fatigue, spring drift, spring decay, and/or one or more unnoticed broken springs in a spring nest. Non-existent springs cannot fail.

"A review of nuclear industrywide pneumatic system problems indicated that 49 percent of all failure events resulted from contamination in the system...the principle source of foreign material is rust within the instrument air system and induction of foreign material (primarily dirt) with the air intake."

Have you ever wondered why there is so much contamination inside actuators? It's not all from "instrument air". No matter how well-built, any actuator with springs will vacuum in the environment into the actuator, wrecking the seals and the springs.

The Easytork actuator always exhausts out instrument air. The environment will never enter an Easytork actuator because of our usage of an air reservoir as a fail-safe mechanism.

Mining Case Study: Easytork Actuators Thrived in Challenging Application and Reduced Total Cost of Ownership for Operator

Read Case StudyNote: You may turn on volume directly in video

It is not just that we have one moving part and no springs. The way our actuator moves is as simple as it gets. Easytork's one moving part creates pure rotary-to-rotary movement. Rack & pinions convert linear-to-rotary movement.

For any questions on Easytork’s pneumatic actuator working principle, please contact us!

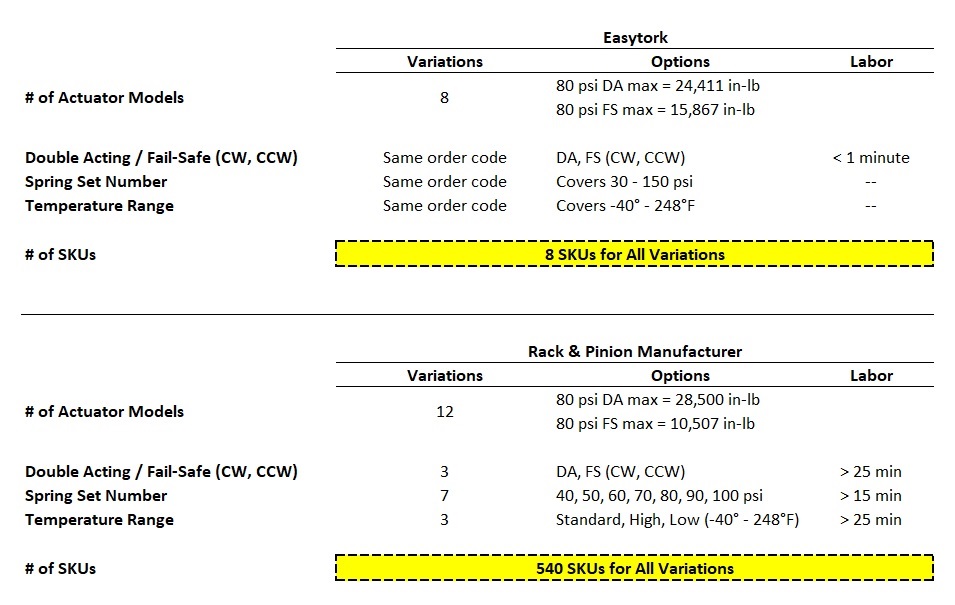

How much capital is invested in your stock room and how many lines of bill of material are inputted in your asset management system? Think about all the actuator functions you need to prepare for: double-acting, fail-open, fail-close, 60 psi air supply pressure, 80 psi, high temp, low temp, etc. You get the point. And if you don't have it at a moment's notice, how much time is maintenance spending to configure to the required function(s), and how much in $ premium are you spending for overnight need? It's a lot, and we get it.

Each Easytork actuator will cover all but the most extreme applications you will need. That's a lot of operational and time savings. Need to convert an actuator from double-acting to fail close or fail open or vice versa? It will take maintenance 60 seconds to change our actuator's functions. Have a high temperature or low temp application? Our standard line is already made to cover this wide temperature range.

Have you ever had to install or remove springs in order to switch functions of actuators? We have, and this process annoyed and scared us. Just ask your maintenance if they ever had a close brush with getting hurt by springs.

Our solenoid/pilot/trip valve manipulates how the air path flows within the Easytork actuator based on the knob adjustment and installation orientation.

Air reservoir drives actuator fail-safe when supply air pressure drops below trip valve's trip point. It fails in the close or open position by how the air line is connected between the actuator and the reservoir. Our patented design simplifies the trip valve and the piping between the actuator and air reservoir into one clean package so that it takes less than 60 seconds for someone to change the function of an Easytork actuator.

Double Acting: Pipe actuator directly or leave solenoid valve knob outward

Fail Close: Install the solenoid/pilot valve, push solenoid valve knob inward

Fail Open: Install the solenoid/pilot valve upside down, push solenoid valve knob inward

Modulating (Double Acting, Fail Close, Fail Open): Same concept as above, except use the NAMUR Trip Valve (NTV) instead of our solenoid/pilot valve for fail safe.

Note: You may turn on volume directly in video

Eliminate up to 67x inventory and supply chain considerations. Our eight actuator models cover multiple functions and solutions, allowing operators to get up and running quickly without having to worry about stocking a multitude of parts, bill of material, and assembling on-site. Plus, no dangerous springs to work with.

Source: Publicly available catalogs of rack & pinion actuator manufacturers.

We eliminated 27 different rack & pinion actuator SKUs and replaced them with just FOUR Easytork actuator models.

"Does this actuator fit that valve?" You probably spend a lot of time and money to match different brands of actuators and valves together. Easytork helps simplify things. Our actuators mount to almost all valve brands and actuator accessories such as limit switches and positioners. Whether it's for a new large-scale project, maintenance/retrofit, or a 1 unit replacement, Easytork will bring a peace of mind from planning to installation to operation and get your process up and running quickly.

With multiple flange patterns and VDI/VDE on both sides of the actuator and with adaptable shafts and inserts, the Easytork actuator is the easiest and most adaptable actuator to mount to most valves.

We have one size mounted to a minimum of seven different valves quite easily, with minimum equipment required. So if you upgrade a plant and you wish to reduce your inventory and variability for your maintenance, you can do this with Easytork.

Easytork actuators are more efficient than spring return actuators by almost a multiple of 2x since Easytork does not need to counteract the tertiary spring force that spring-return actuators require. As such, with the same output torque as spring return actuators, Easytork actuators are significantly smaller, lighter, faster, and more cost efficient.

To put this into perspective, a spring return actuator for a 12" butterfly valve would weigh 120 lbs and would require a team to assemble. An Easytork actuator for the same valve weighs 50 lbs and one person can complete the assembly. Easytork's size and weight have significant impact for applications where space is rare commodity such as skid applications.

Fast Acting Solution: Easytork can rotate the same 12" butterfly valve in less than 1 second where spring return actuators take at least 2 seconds or even longer.

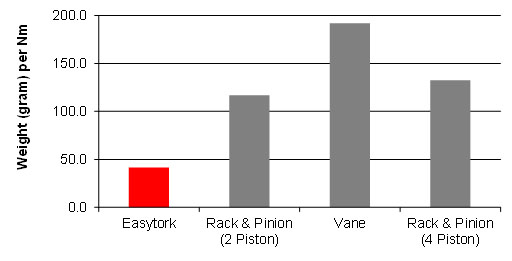

Fail-Safe Size Comparison:

Fail-Safe Weight Comparison:

Before / After Easytork Installation Comparison:

Footprint Reduction Case Study

Read Case Study

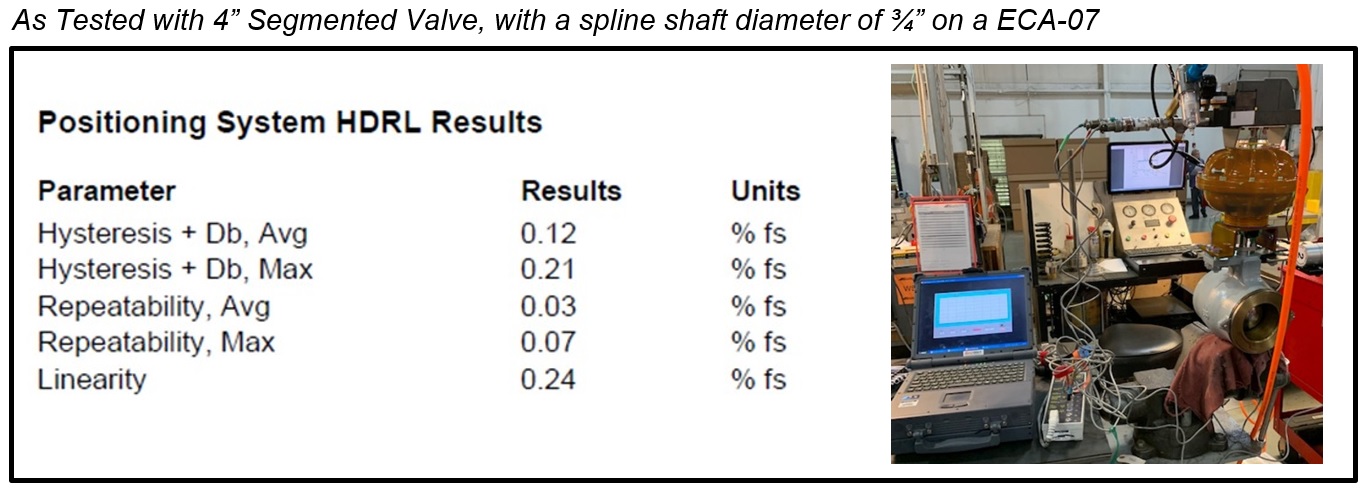

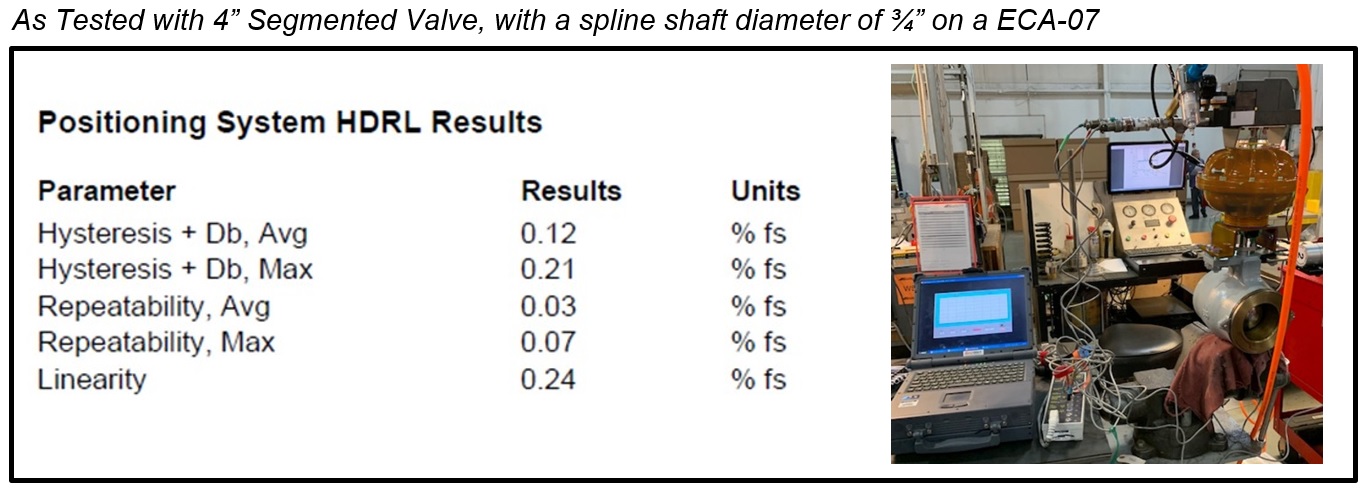

Limited by control valve speed of response (Lambda or T86) for small or large step changes? Our technology is a paradigm shift of what is attainable. It combines fast-acting and accuracy into one package.

The Easytork Control Actuator line is a game-changing development for the pneumatic actuation and control valve markets. It replaces the rotary spring & diaphragm style actuator’s reason for existence. Compared to RS&D, the ECA has better accuracy and is more economical, 1/10th to 1/4th the weight, 1/6th to 2/3rd the size, and consumes 1/4th to 1/2 the air consumption.

The ECA is the only rotary-to-rotary actuator that couples directly with rotary control valve’s shaft. With the cleanest motion transfer between valve and actuator, Easytork is able to achieve high degrees of accuracy to the control valve.

| Model 0309 | Model 0411 | Model 0514 | Model 0717 | Model 1022 | Model 1227 | Model 1436 | Model 1646 |

|---|---|---|---|---|---|---|---|

| 0.2 sec | 0.3 sec | 0.4 sec | 0.5 sec | 0.6 sec | 0.9 sec | 1.5 sec | 3.5 sec |

Note: Positioner quality may limit the actuator's full potential accuracy and speed.

When the available air supply pressure to the actuator is 35 psi or below, prior to Easytork, the only suitable option was the spring and diaphragm actuator. Spring-return actuators, such as rack and pinions or scotch yokes, require a minimum of 40 psi and are therefore unsuitable. Easytork actuators, however, can operate and fail-safe at air supply pressures of 30 psi or below.

Applications for low air supply pressure include, but are not

limited to:

- Actuators connected to a P/P controller, as most P/P controllers have a maximum rating of 35 psi.

- Remote locations, such as oil and gas tank batteries.

While increasing the air supply pressure is possible, this is often impractical as it requires altering the end-user’s air

system design. The ideal solution is to use an equivalent low pressure actuator that can be easily integrated without

modification.

Detailed Low Air Supply Pressure Case Study:

Read Case Study