Skid Case Study: Footprint Reduction

Easytork Actuators Reduce Size and Weight Limitations

SUMMARY:

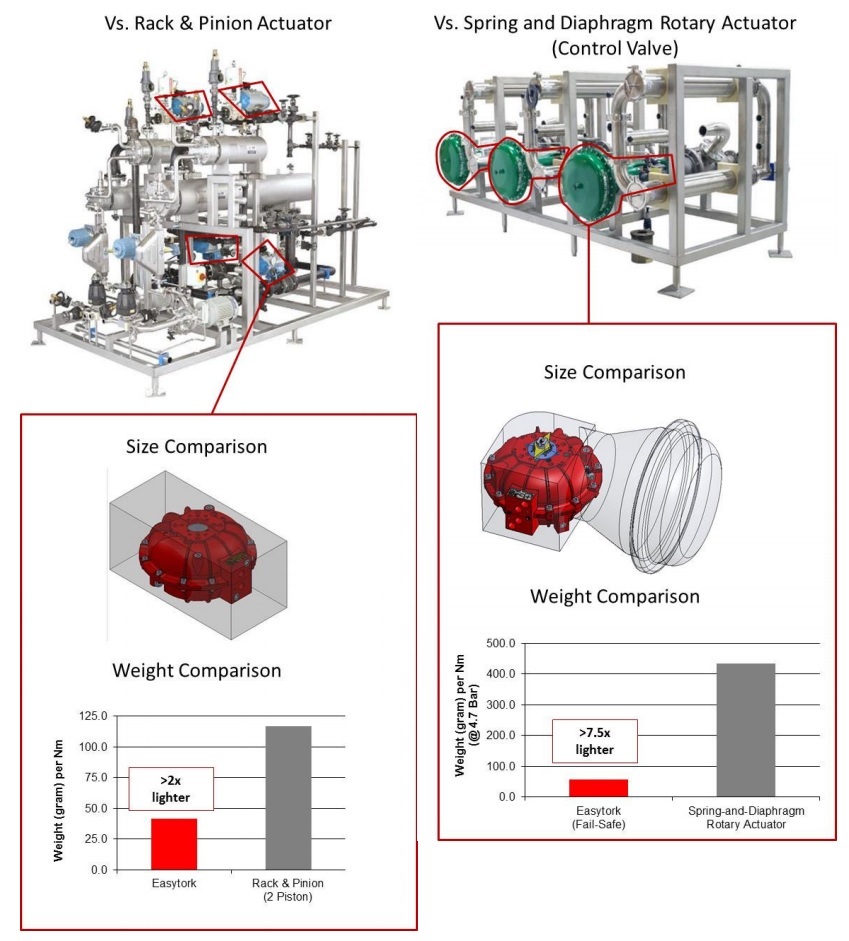

Industry experts in skid manufacturing know the importance of available space on their skid system especially when the skid system occupies valuable floor space. The problem with size is amplified with larger line sizes, since the actuator required becomes progressively larger.

Easytork actuator complements the skid manufacturing market requirements with an actuator that is the not only the smallestin-class actuator but is also the lightest-in-class actuator in the market

CHALLENGE:

A global skid manufacturer was battling a combination of size and weight limitations. The problem was compounded by one of the processes utilizing a cavity filled seat, which doubles the valve’s original torque; resulting in the actuator size and weight exceeding the available space and support structure available.

Adding to the challenge was the end-user’s preference for triclamp connections. The integrity of the connections would be challenged with a heavier package. In general, the possibility of a sturdier tri-clamp can be resolved through support bracket to the skid frame. However, the additional cost, labor and design were not an option in this case.

The initial challenge was to find an actuator with a limited size footprint. The secondary challenge is to reduce weight.

SOLUTION:

Starting in 2016, and continuously since, Easytork actuators were installed on different skid services including on water, ink, air, solvent, among other applications.

The size of the Easytork actuator is drastically smaller and easier to incorporate into the skid system. The reduction in the weight reduces support structure and labor required.

Easytork is considered a low maintenance actuator, which does not require emergency replacement or maintenance.

RESULTS:

Need More Information? Let Us Help You.

314-266-6880, info@easytork.com, or Live Chat with Customer ServiceSend Us a Message (Same Business Day Response):